Fill In the Certificate Sections¶

You do not have to fill in a certificate in any particular order, but at the very least we recommend you complete the Supply Details section before adding any boards. This enables the software to perform various calculations on the fly, such as determining the required equipotential bonding sizes from the type of earthing system and size of supply cables.

Installation Details¶

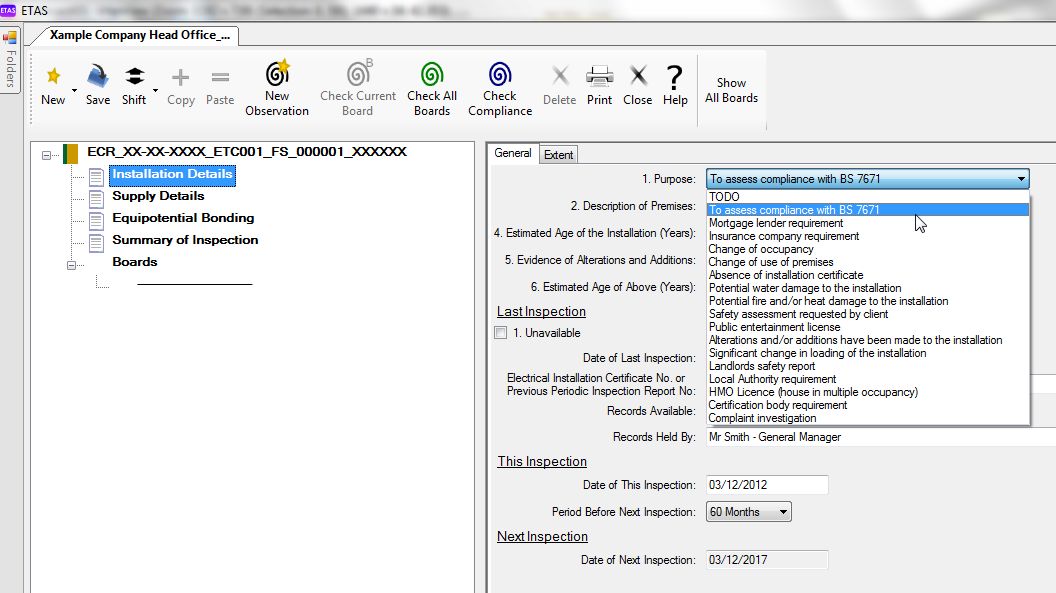

- In the left tree click “Installation Details” then select the “General” tab on the right pane.

- Fill in fields on the General tab.

Note:

If the last inspection report is unavailable, select the “Unavailable” checkbox.

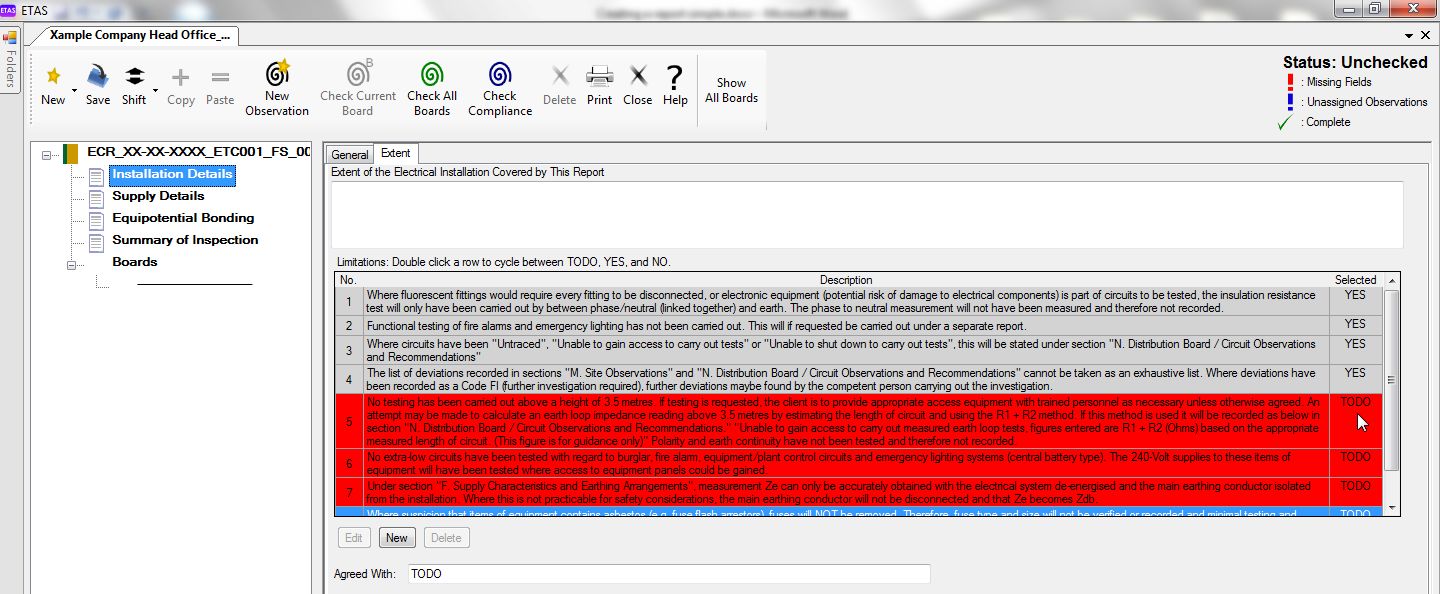

- Select the “Extent” tab, and in the top section describe the extent of the testing that will be carried out.

- In the bottom section, select, deselect or add limitations.

- Limitations highlighted grey are presets that you cannot alter.

- Limitations highlighted red are presets that you need to explicitly select or deselect. To select or deselect a limitation, double-click it.

- To add a custom limitation, click New.

Supply Details¶

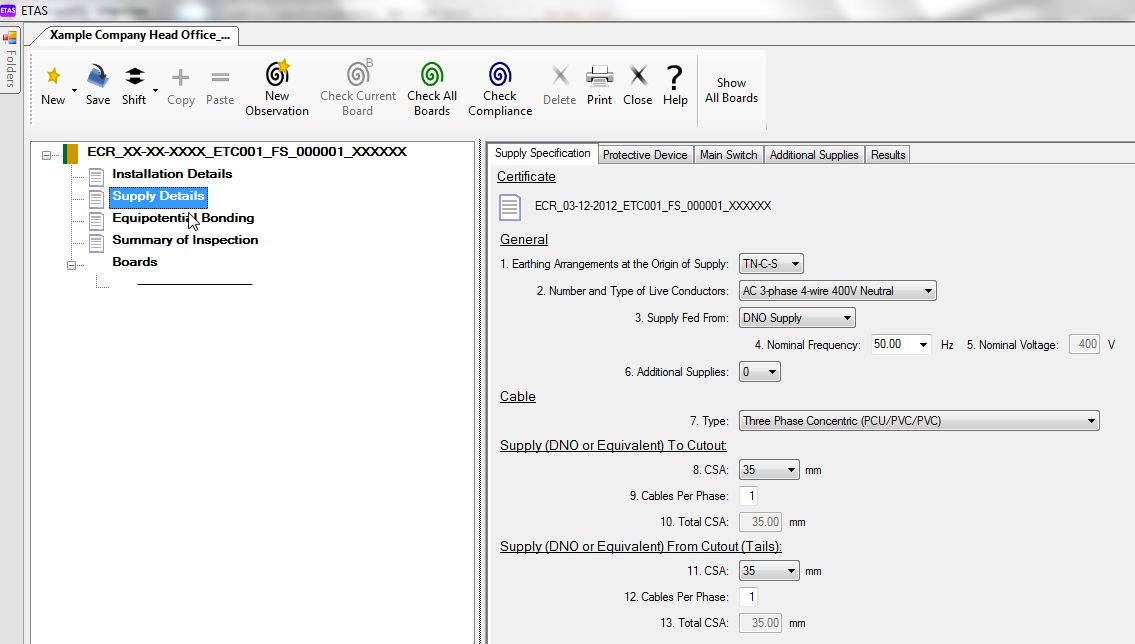

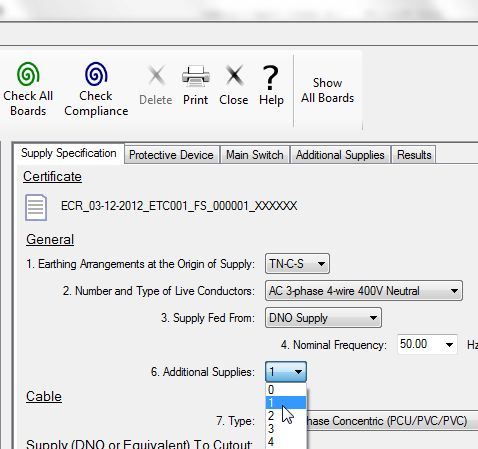

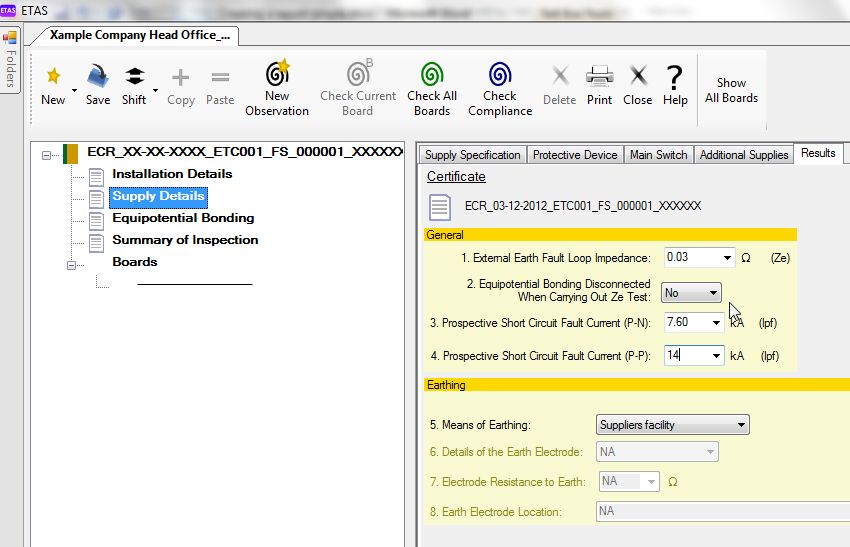

- In the left tree click “Supply Details”, then select the “Supply Specification” tab on the right.

- Enter the details of the supply.

Note:

A common error made with the details of the supply is where the “tail” size and type are entered, this is not correct; it is the actual supply entering the building that must be recorded as the equipotential bonding is based upon the supply neutral in the case of a TNCS (PME) earthing system. Therefore, both the main supply cable(s) and “tail” sizes are recorded for automatic calculation of the equipotential bonding and earthing conductor requirements.

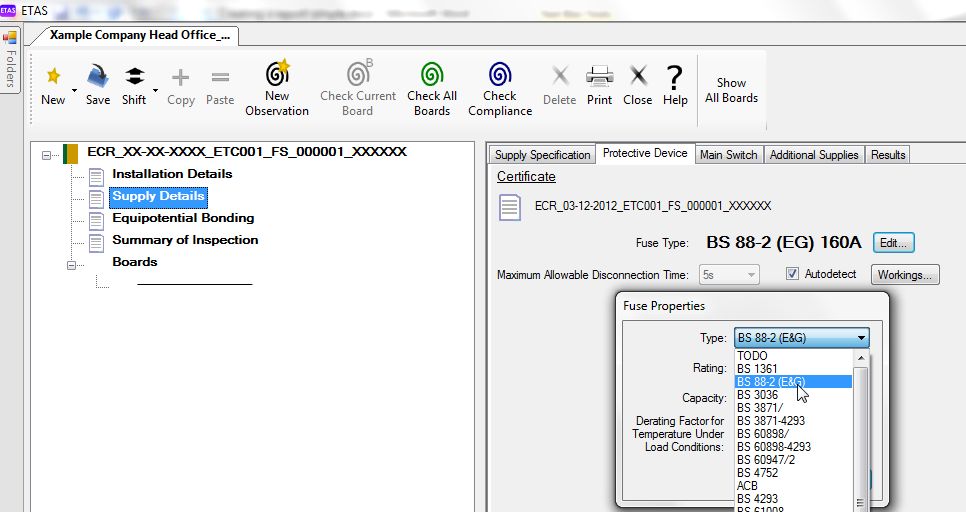

- Select the “Protective Device” tab and enter the main supply fuse. Where possible, the software will fill out details for you. In this case, as we know it is a “3-phase 4 wire” system and the fuse chosen is a BS 88 type the breaking capacity is entered (80 kA) automatically (this may be over-written).

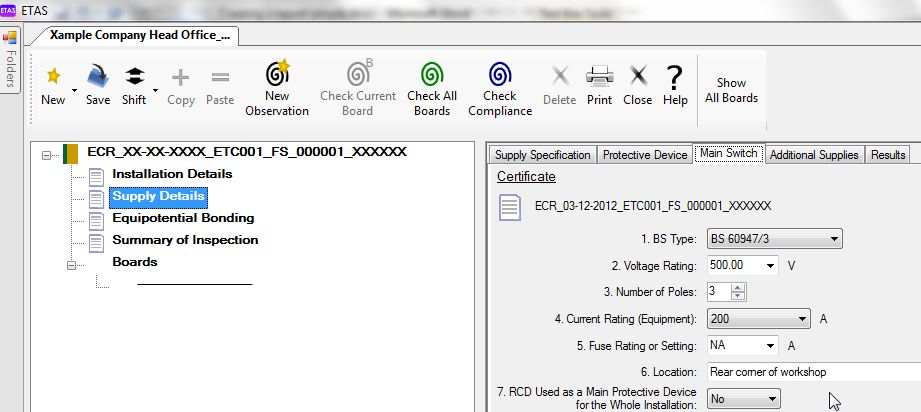

- Select the “Main Switch” tab and fill out the details.

Note:

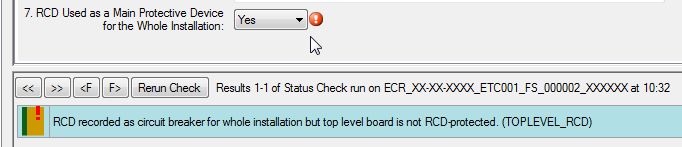

If you have an RCD unit either in a “board” or as a separate unit protecting the complete installation, enter “Yes”. When you record your first “board” and you inadvertently choose a non RCD protected “board”, when you eventually click the |check compliance icon| button it will remind you. As calculations are carried out on the “fly”, you can insert an RCD protected item at any time.

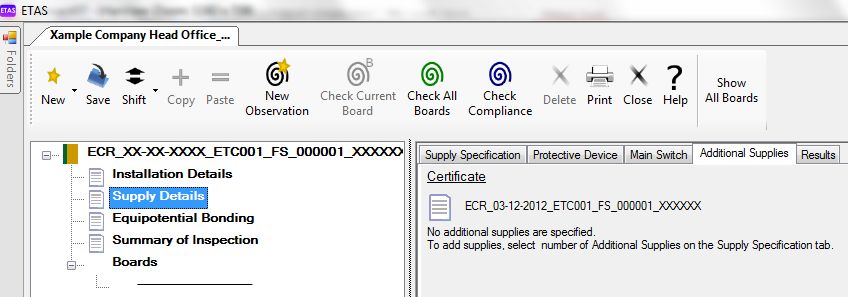

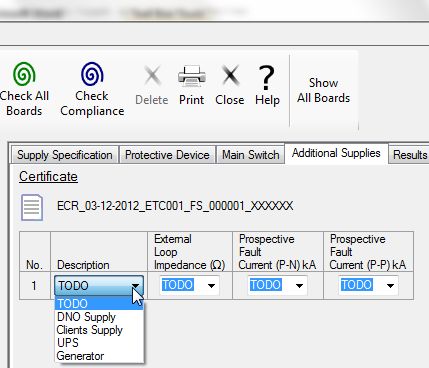

- Select the “Additional Supplies” tab and confirm that there are no additional supplies.

Note:

If later you find there is an additional supply from say, a generator, enter the number of supplies on the “Supply Specification” tab and describe them on the “Additional Supplies” tab.

- Select the “Results” tab and fill in the measured values.

Equipotential Bonding¶

Now enter the equipotential bonding conductor sizes.

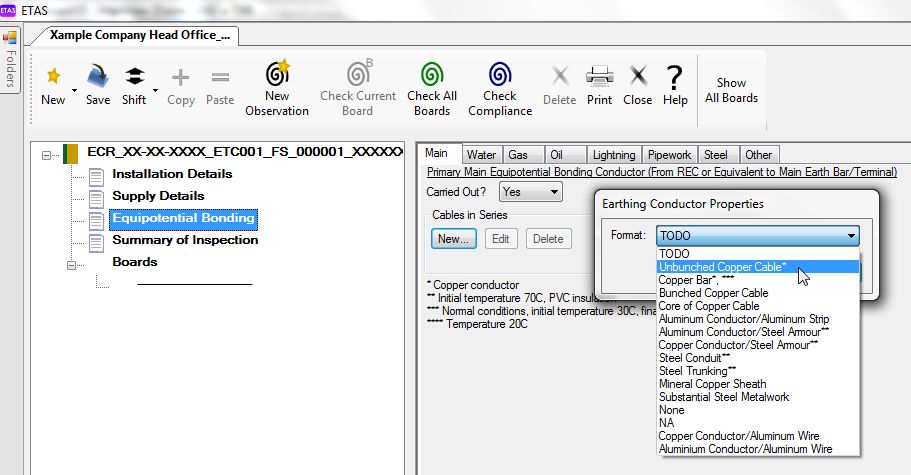

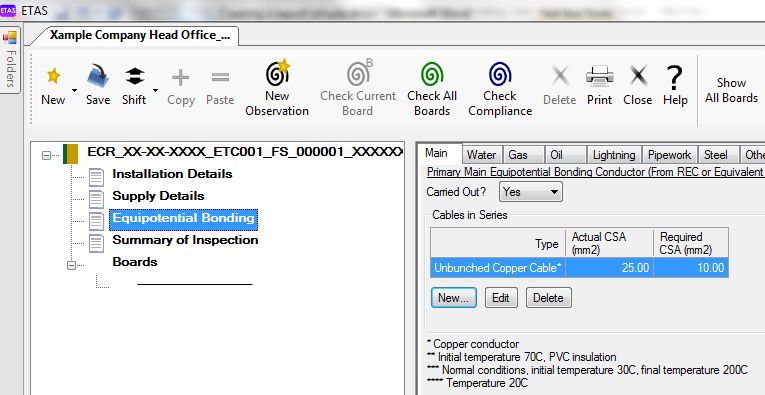

In the left tree click “Equipotential Bonding”, then select the “Main” tab on the right.

Enter the details of the main equipotential bonding conductor.

This conductor may, from the DNO connection, connect to a MET or may connect to the distribution board from which all other equipotential bonding conductors are connected. This conductor usually is both the main equipotential bonding conductor and the primary earthing conductor for the installation.

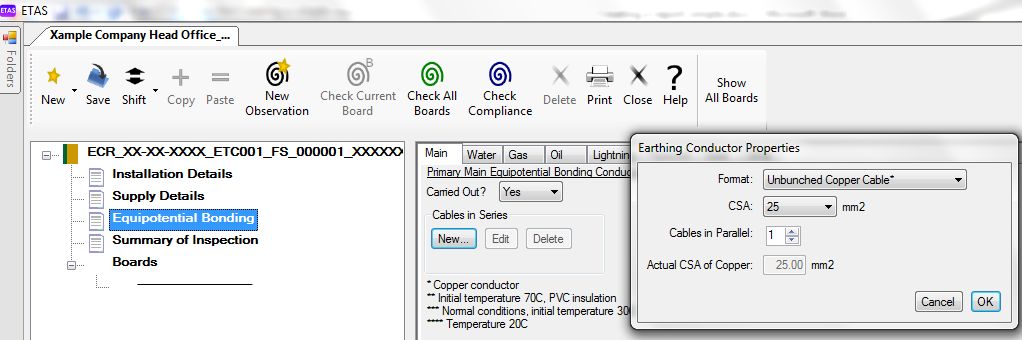

Here you can see that we have chosen an “Unbunched Copper Cable” with a CSA of 25.00 mm. If you have more than one cable in parallel, enter the number and the software will calculate the actual CSA of copper and/or equivalent if armouring, trunking etc. is being used.

Once entered, the software will calculate, based upon the type of earthing system recorded earlier, the equipotential bonding size required; here showing a requirement of 10.00 mm. (If changes are made to the type of earthing system, do not worry as calculations are made on the fly and will update automatically).

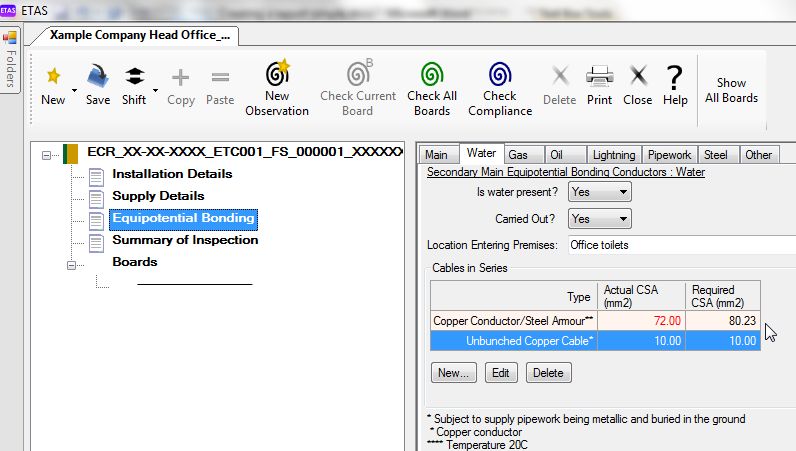

Next record the equipotential bonding to the water service.

The water service equipotential bonding is wired via the armouring of a 25.00 mm 4-core SWA sub-main cable supplying the office distribution board. From the office distribution board the water service is connected via a 10.00 mm cable (this will stimulate an automatic observation when then final compliance check is carried out - undersized cable will highlight in red).

You can record as many different types and/or sizes of cables in series as are installed. If you have more than one cable in series, click on “New” for each cable and enter the details; if you require either to edit or delete a cable, highlight the cable in question and click on “Edit” or “Delete” accordingly.

Now enter the rest of the equipotential bonding details.

At this point, skip the “Summary of Inspection” as most fields are linked to auto observations and are flipped from “To Do” to the relevant observation code automatically. This section is now complete and we will start to record distribution boards and circuits.

➲ Next: Add Boards.