Features (Contractor/Engineer)¶

Intelligent circuit analysis and diagnostics.

“On-the-fly” calculations to aid engineers while testing.

Data integrity. Signed-off certificates are read-only. Working copies generated from signed-off certificates are editable but have all references to the original contractor/inspector removed to avoid compromising signed-off data.

Hundreds of preset observations with default category codes helping promote consistency, especially where more than one inspector is involved.

Auto Observations

Over 130 editable observation templates with default category codes for diagnosing automatically detected conditions by calculation. Templates are filtered according to the observation context for ease of use by the Inspector.

Preset Observations

Over 500 searchable and editable templates for observations that are not reliant on being produced by calculation (e.g. Electrical equipment marked incorrectly Regulation 514.9.1) complete with regulation number and default category codes for ease of use by the Inspector.

A Summary of Inspection that includes all special locations (except medical) with preset editable observations.

Semi-automated filling in of the lengthy “Summary of Inspection” report section through analysis of chosen preset observations (“Flipping”).

Where alterations or additions have been made to an existing installation or remedial works carried out, copies of the data can be exported in full (including test results) to create an Electrical Installation Certificate.

PDF reports can be customized with the issuer’s logo and letterhead.

Visually descriptive icons for identifying phase group (single phase, 3-phase etc.)

Copy and paste circuits for faster data entry.

Copy and paste of boards across files enables multiple inspectors to work on the same installation in parallel.

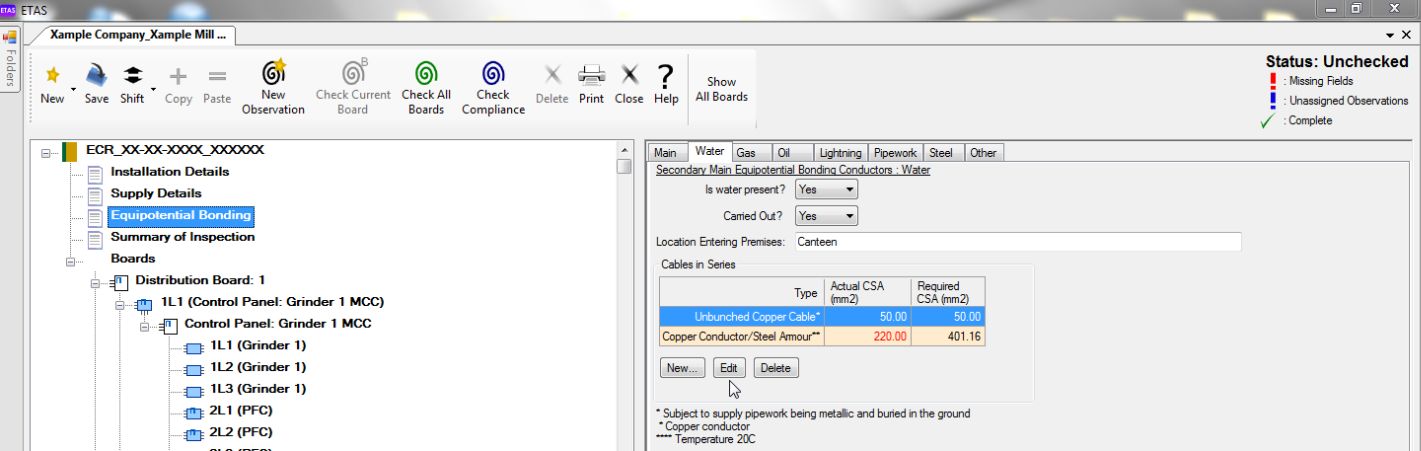

Equipotential Bonding

Verification of size of equipotential conductors with regard to the type of earthing system (TNCS, TNS or TT) and type of conductors used (i.e. copper, copper sheath, steel or aluminium armour, trunking, conduit etc.) in relation to Regulation 544.1.1 and table 54.8 of BS 7671. You are also able to record multiple earth conductor types in series with the end report showing the smallest size in use.

You can also record whether more than one bonding cable has been installed in parallel. Here you can see that there are two cables being used in series for the equipotential bonding to the water supply. As the earthing system is TNCS it is calling for a 50.00 mm copper cable or equivalent. The steel armouring used should be approximately eight times the size of the required copper. The undersized cable is highlighted in red, and an auto observation will be offered when automatic compliance checking is carried out. Where a supply has been taken to a separate building, the equipotential bonding sizes of that building, if required, are calculated and recorded on the distribution board test sheet. You can also record a change of earthing system, if for example the earthing system changes from a TN** to a TT system, and the calculations will be updated accordingly.

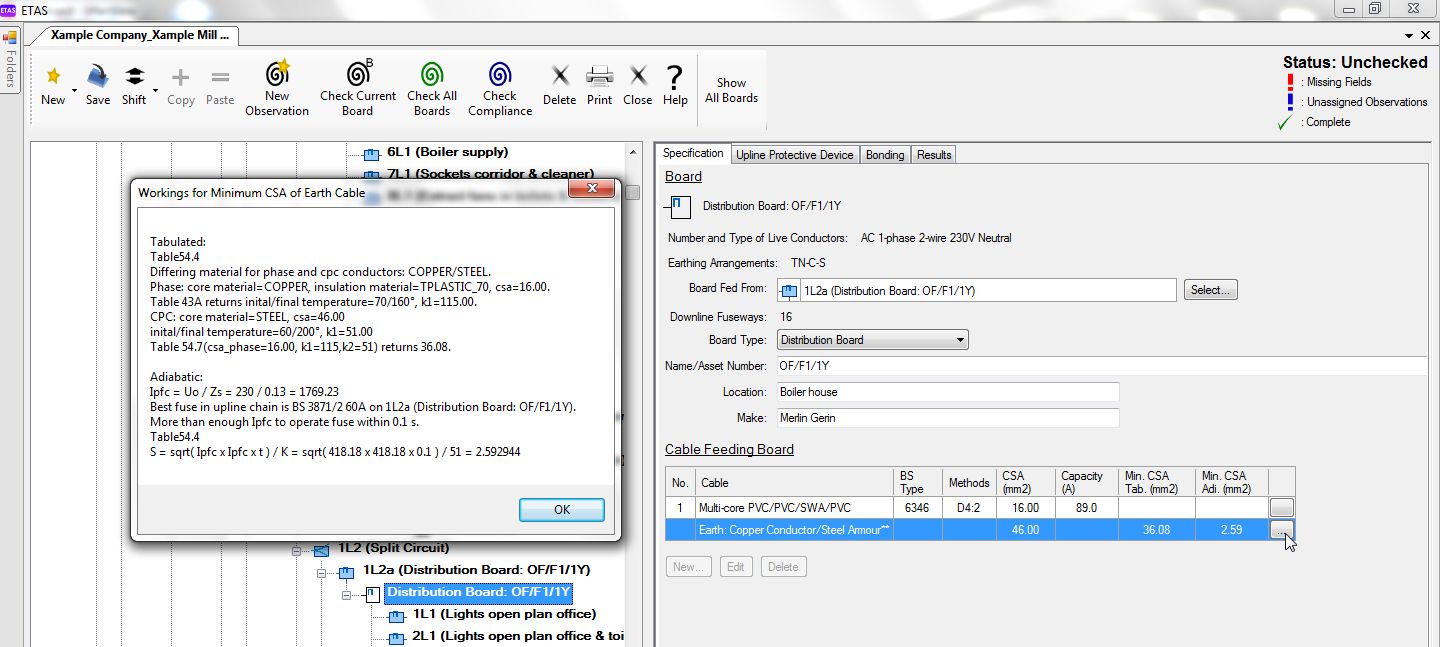

Earth Conductor

Verification of size and type (copper, copper sheath, steel or aluminium armour, trunking, conduit etc.) in relation to the phase conductor as per table 54.7 of BS 7671 and calculated by the use of the adiabatic formula using tables 51.2 to 51.6 of BS 7671, and in relationship to the earth loop reading taken at the end of the circuit.

You can also record multiple earth conductor types and sizes in series, with the end report showing the smallest size in use (equivalent in copper where steel is being used). You can also record whether more than one earth conductor has been installed in parallel.

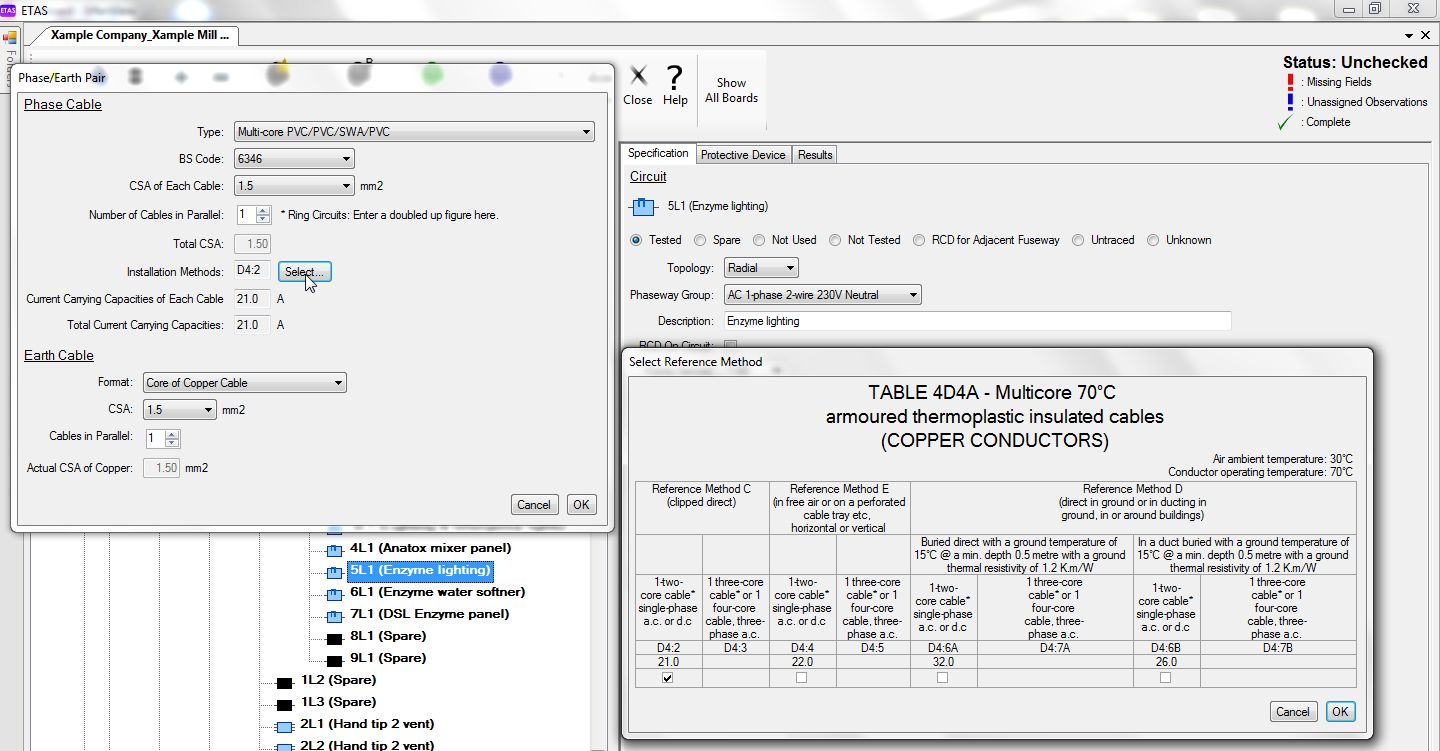

Phase Conductor/Protective Device

Verification of size and type of cables with regard to method of installation as per tables 4D1A to 4J4A and the size of the protective device either local to the circuit, or all the way upstream to the source.

You have the ability to record multiple cables (in series and in parallel), multiple cable sizes, types and methods of installation with the end report showing the minimum current carrying capacity cable. For example: A cable feeding a piece of electrical equipment in an outside building is firstly installed in conduit, then connects to an armoured cable being buried, whereupon on arrival at the outside building it is then jointed to two 6242Y twin and earth cables. All cables and methods of installation are recorded in the data set with the smallest current carrying cable by either size or method of installation entered onto the report.

Calculation of cable carrying capacity subject to type of load and sizes of protective devices in chain:

Example 1

A 2.5 mm cable by the method of its installation is rated at 25 amps and has an inductive load, therefore requires overload protection. The local fuse protecting this circuit is rated at 32 amps. Upstream of this circuit is a 20 amp protective device - therefore it will pass for over load protection. If there was not a limiting protective device upstream the software will offer an observation to be recorded.

Example 2

A 2.5 mm cable rated at 25 amps having a protective device rated at 32 amps supplying a 3 kW night store heater which is a resistive load only with the cable having no branches/spurs between source and the load. As the smallest protective device in the “chain” is 32 amps, the software will ask automatically whether the load is resistive or inductive. If resistive is chosen it will ask whether the load is greater than 25 amps. As this is a resistive load only and is limited at 12.6 amps, overload protection is not required and the software will pass this circuit for overload protection. If the load was greater than 32 amps, the software will offer an observation to be recorded.

Example 3

A sub-main feeding a distribution board is wired in 16.00 mm cable with a rating in accordance with its method of installation of 63 amps. The smallest upline protective device is rated at 100 amps (as above, it will take into consideration all up-stream protective devices). The software will calculate the potential downstream load. It can do this by totalling the downstream protective devices, (see note) and/or if applicable, overload devices per phase at their face value i.e. a 6 amp device is counted as 6 with the exception of a ring main, which although has a 32 amp protective device is load rated at 26 amps. If the total fuse count per phase is less or equal to 63 amps, the software will pass the sub-main circuit for over load protection. If the total load per phase is greater than the current carrying capacity of the cable the software will offer to record an observation.

- Note

- The protective device type and size of any circuits marked as “Untraced” or “Unknown” must be filled in for the program to be be able to sum the potential load.

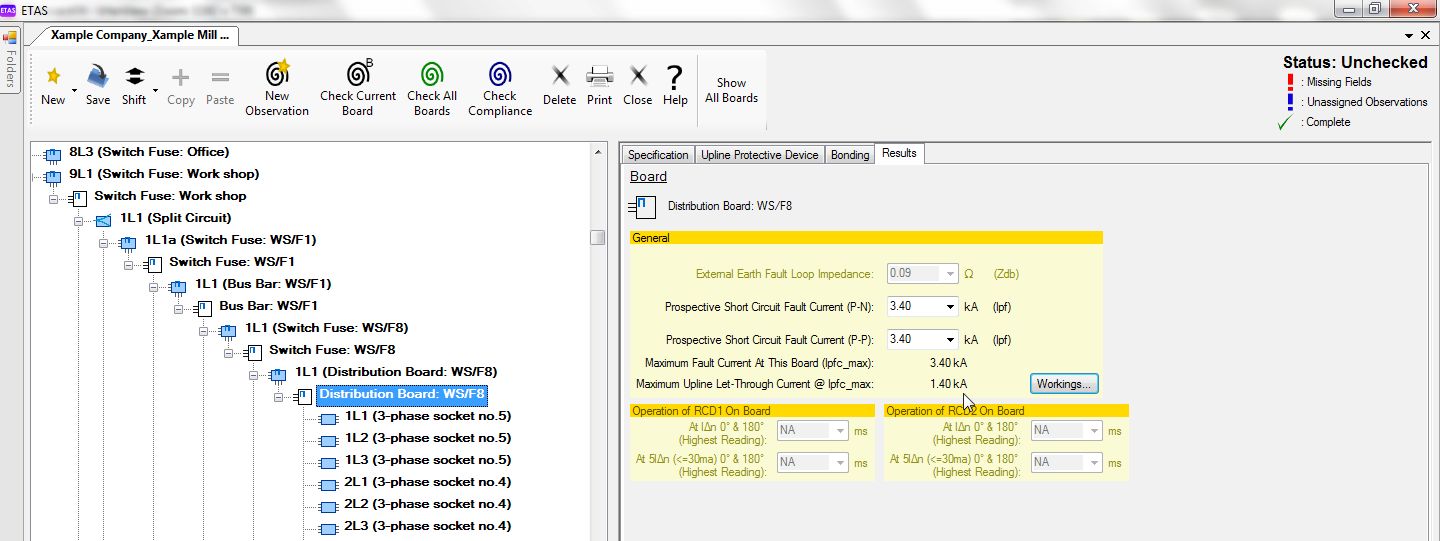

Protective Device Let-Through Energy

Where any protective devices in the chain afford let through energy protection (e.g. BS 88, BS 1361 protective devices and some electronically controlled MCCBs), the let through energy is calculated at all relevant points (at the point of insertion of a downstream protective device).

Example: An MCB with a breaking capacity of 9000 amps (9 kA) has been installed. The maximum measured fault current at this point is 12000 amps (12 kA). A BS 88 160 amp protective device has been installed upstream. The “let through energy” of a BS 88 160 amps with a measured or calculated prospective fault current of 12000 amps (12 kA) will limit the “let through energy” to approximately 5500 amps (5.5 kA). Therefore the breaking capacity of the local MCB (9 kA) will pass with a local PFC reading of 12 kA. Note: If more than one limiting protective device is installed upstream the software will record and base its calculation on the best possible device as calculated.

- RCD/RCBO

Automatic calculations carried out with the presence of RCD/RCBO protected circuits.

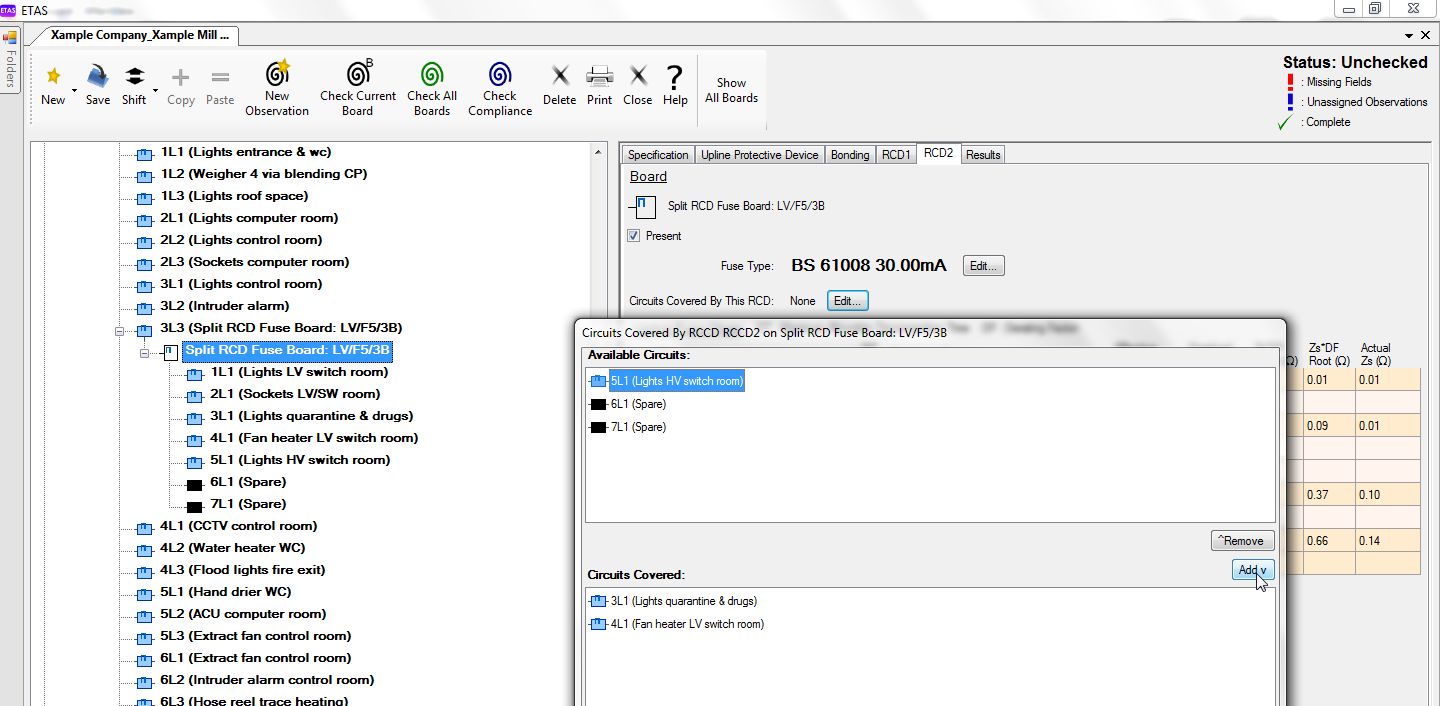

Example 1 You have a fuse board with additional protection afforded by an RCD. From the drop-down list of types, choose “RCD protected fuse board”. Enter the relevant RCD data and the “Maximum ZS permitted by BS 7671” is automatically entered on all circuits based upon the mA rating of the RCD/RCBO.

Example 2 You have a split load fuse board with 1 or 2 RCD’s. From the drop down list of board types, pick “Split RCD protected fuse board”. If the fuse board has 1 x RCD then enter the relevant details of the RCD are along with the relevant circuits protected. If the fuse board has a second RCD, select the “Present” checkbox and pick the relevant circuits. The “”Maximum ZS permitted by BS 7671” is automatically calculated on all circuits based upon the RCD/RCBO’s.

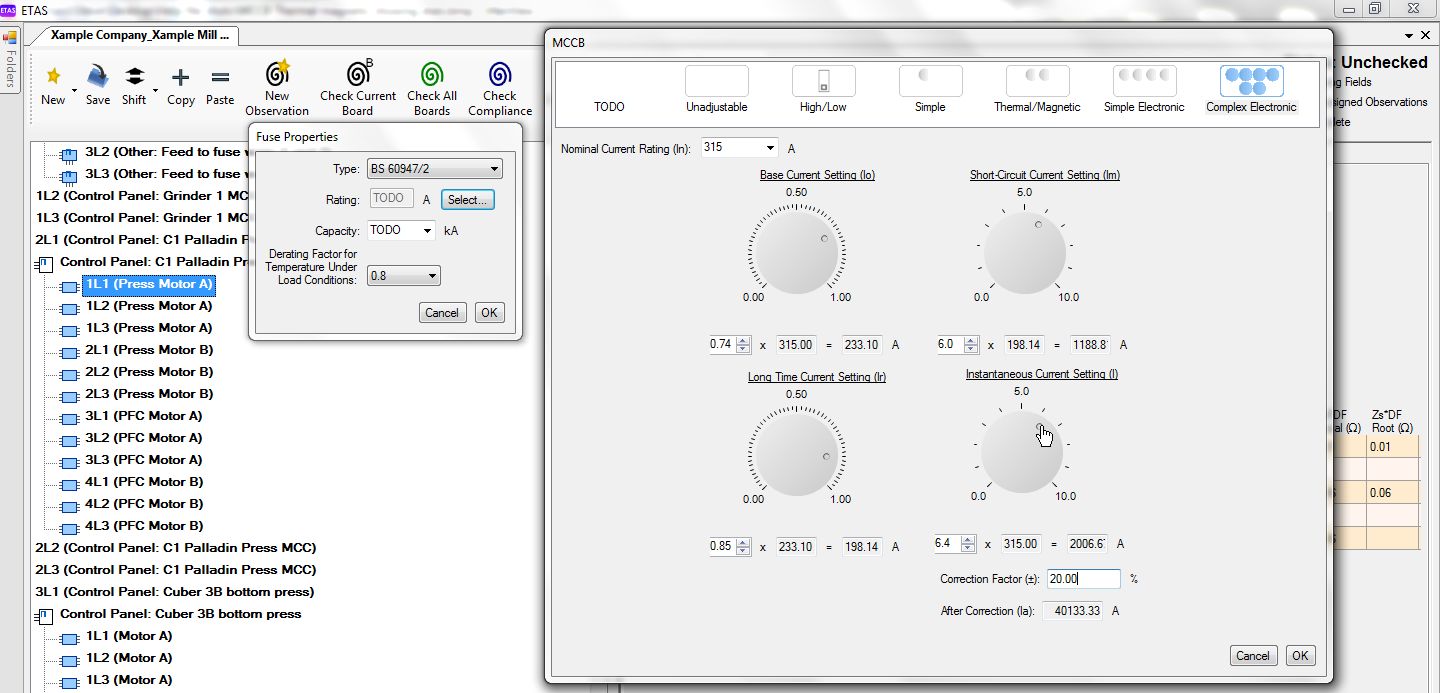

MCCB/ACB

If an MCCB or ACB is chosen as a protective device, you can drag the dials with the mouse or enter the settings directly with the keyboard.

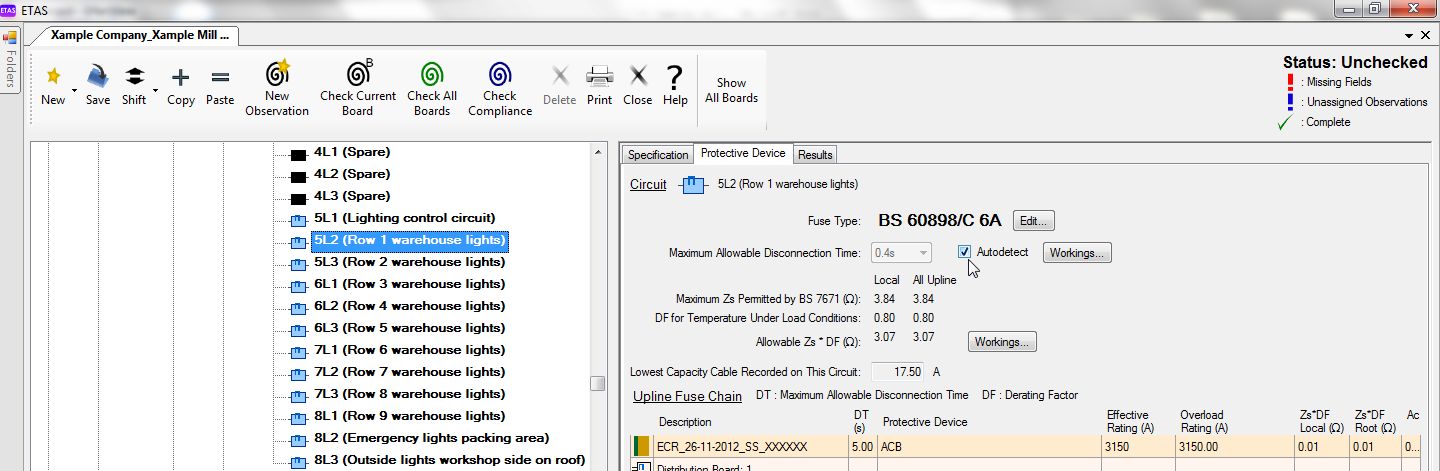

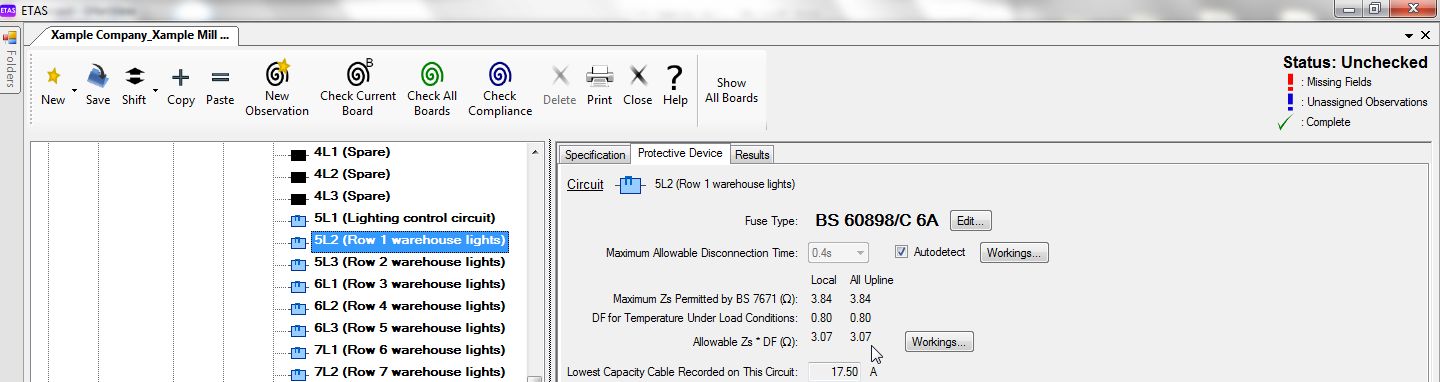

Maximum Disconnection Times

Based upon the type of circuit and the type of earthing system, the maximum disconnection time is automatically entered. For example, if a sub-main circuit is chosen on a TN** system, 5 seconds is automatically entered. If a radial or ring main circuit is chosen and the protective device is 32 amps or less on a TT system, 0.2 seconds is automatically entered. This is a default setting which may be altered by deselecting the “Autodetect” checkbox in the very rare circumstances where a protective device is greater than 32 amps, but is a circuit that has a protective device that should operate in 0.4 seconds. For example, where you might have a ring main with a 40 amp protective device and the software enters 5 seconds automatically, you can override this and change it to 0.4 seconds or 0.2 seconds subject to the earthing system.

- Note:

- The program will detect that the ring main is protected by a protective device that is too large and offer an automatic observation.

Short Circuit Capacity

Where BS 88 or BS 1361 type fuses are entered, the breaking capacity is automatically entered based upon the line voltage of the circuit.

Maximum Zs Permitted by BS 7671

Figures are calculated automatically from the protective device chosen and whether low voltage or reduced low voltage 110V single phase (Uo 55 V) or 110 V 3-phase (63.5 V), subject to the type of circuit chosen (sub-main, ring or radial) and type of earthing system with regard to the maximum allowable disconnection time.

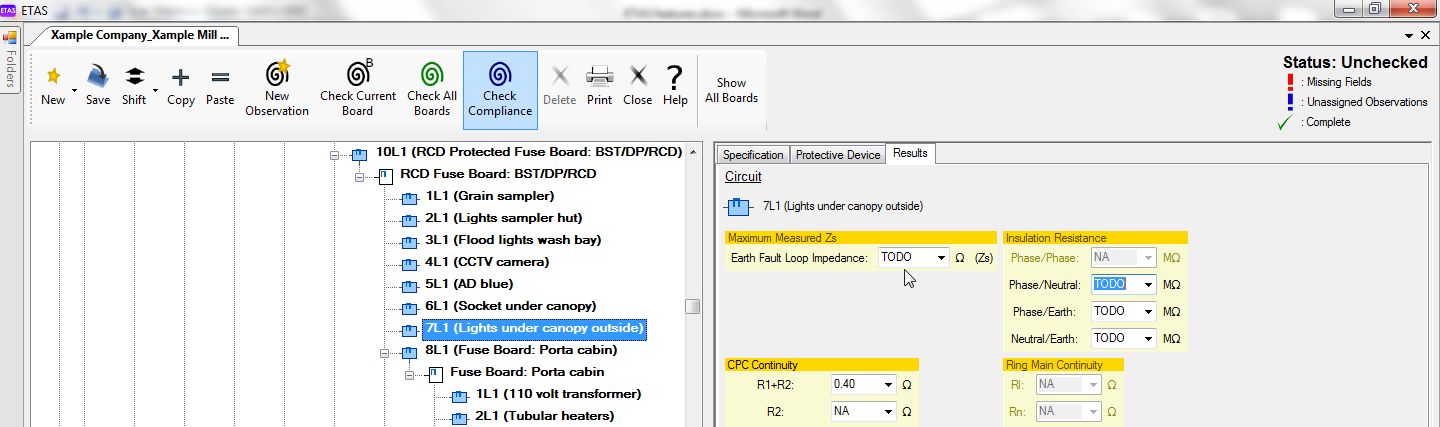

Earth Loop

You can enter the earth loop reading directly into “Earth Fault Loop Impedance” field. Alternatively, you can enter a R1 + R2 reading into the “R1 + R2” field and if the earth loop field is set to the default “To Do”, the software will automatically add the earth loop reading of the distribution board (Zdb) to the R1 + R2 reading and update the “Earth Fault Loop Impedance” field.

Insulation Resistance

The software will detect the circuit line voltage and grey out redundant fields. For example, if a 230 V circuit is chosen, the “Phase/Phase” field will be greyed out. Similarly, if a multi-phase circuit without a neutral is chosen, then both the “Phase/Neutral” and “Neutral/Earth” fields will be greyed out. In the case of an Electrical Condition Report, if “Phase/Phase” or “Phase/Neutral” has “UTT” (unable to test) applied, this will be ignored by the compliance check and no automatic observation will be offered. This is due to being unable to carry out these tests on the majority of circuits where items of electrical equipment or accessories would require dismantling and disconnection.

Where results have been entered and are less than 1 MΩ an automatic observation will be offered.

Ring Main Impedances

Based upon the type and size of cabling used for a ring main, the program analyses the differences between the recorded values of Rl, Rn, and if applicable, R2. If a differential between Rl and Rn above a certain level is detected, an automatic observation is offered. If steel conduit, MI, armoured etc. is used as an earth then R2 is ignored. Otherwise, if a R2 reading is entered, an automatic comparison is calculated based upon the size of R2 and the size of Rl and if a differential is detected, again, above a certain level, an automatic observation is offered.

RCD/RCBO

Any board RCD/RCBO or circuit RCD/RCBO having time delay abilities can be recorded with all results compliance-checked and an auto observation offered if non-compliances found.

Where a RCD/RCBO has been installed on a circuit, the software will ask if the RCD protects the whole circuit. If there are exposed conductive parts between the source protective device and the RCD (for example, exposed SWA glands, steel conduit, metal RCD enclosure etc.), earth fault protection is reliant upon the protective device protection at the source of the circuit. If there are exposed conductive parts then you would enter “No” (be aware of any branch-offs/spurs before the RCD/RCBO). If all-insulated parts have been used between the source and the RCD/RCBO then you would enter “Yes” (again, be aware of any branch-offs/spurs before the RCD/RCBO).

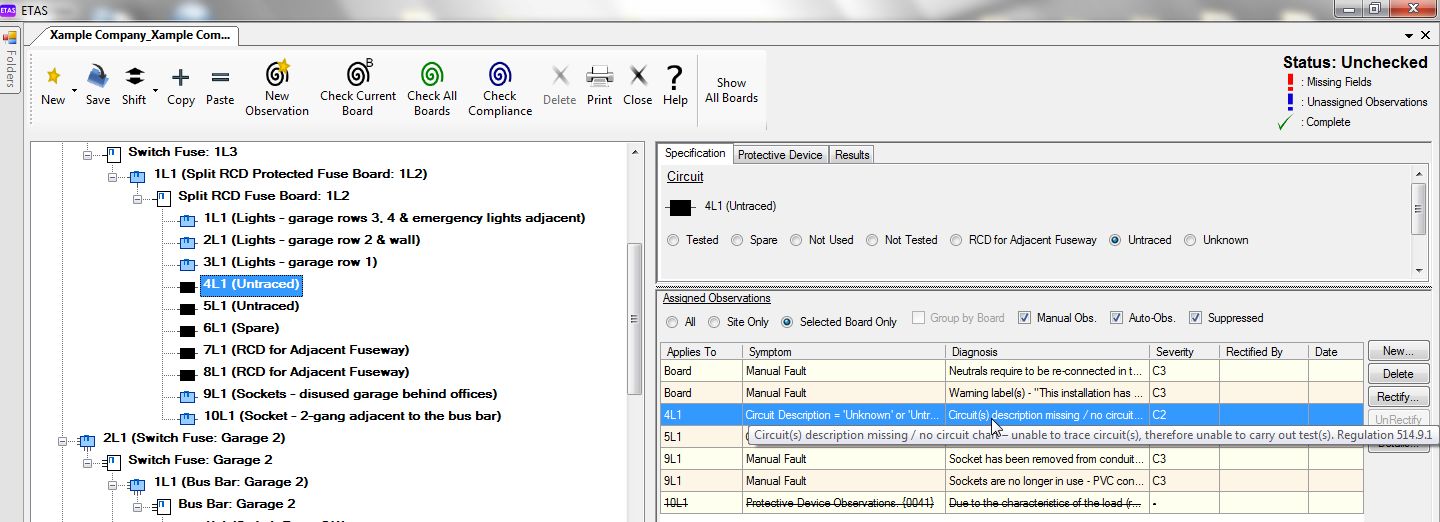

Observations

All observations are displayed in a single, filterable list. Clicking an observation will takes you to the circuit or board in question.

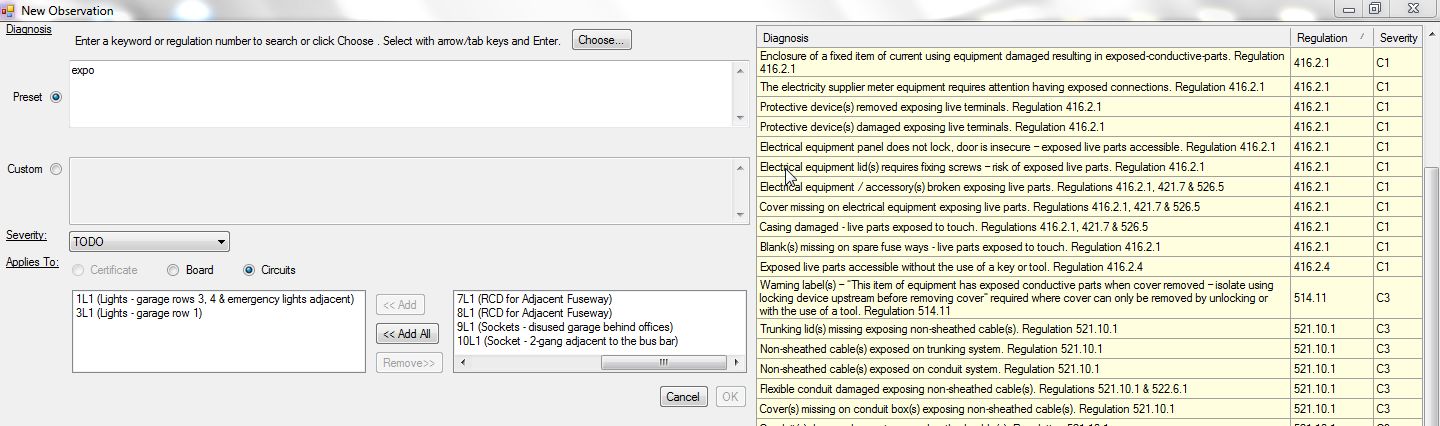

Manual Observations

Picking a manual observation is straightforward: start typing a word and all the observations containing that word will be listed in a popup window on the right.

There are also “hot” words that when typed will list observations that may or may not contain that word, but that are relevant. For example, entering “smashed” or “damaged” will bring up the observation “Electrical equipment / accessory(s) broken exposing live parts Regulations 416.2.1, 421.7 & 526.5”,

You can also enter part of the relevant regulation number. For example, entering “702” will list all observations relating to “702 Swimming pools” and other basins. This is especially useful if an Inspector has limited knowledge of a certain type of Special Location (this does not preclude consulting BS 7671).

Once a preset observation is selected by clicking it, the wording is copied into the Preset text area. Here you can tweak the wording e.g. for extra clarity (the wording must be relevant because once entered and assigned it will flip the relevant field in the Schedule of Inspections). You can also change the default Severity.

Observations can be applied to the site, single boards or multiple circuits. The screenshot below shows an observation being assigned to several circuits.

➲ Next: Basic Concepts.