Add a Split RCD Fuse Board¶

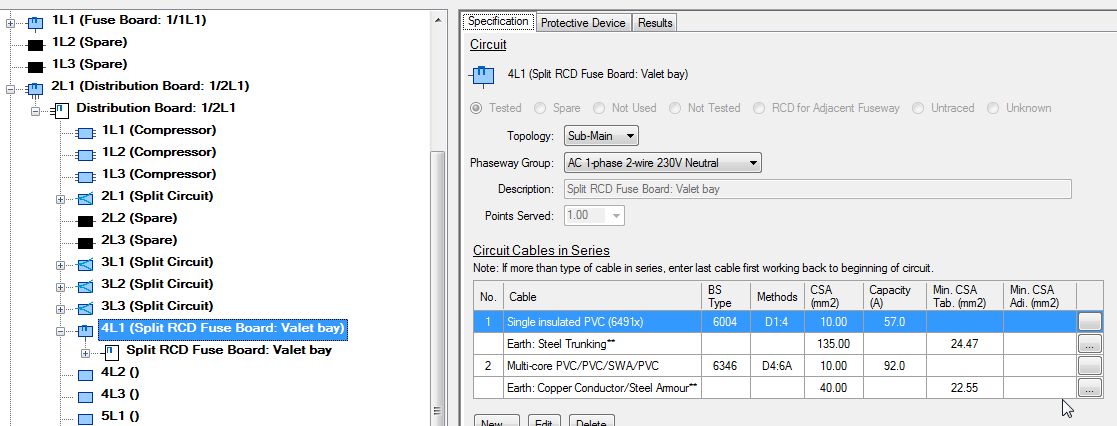

We will now supply a split RCD fuse board which is in the Valet bay situated outside of the equipotential zone having a steel structure, a steel water supply and an air-line fed from the workshop. This supply is on an exported TNCS earthing system. The sub-main is fed via a 63 amp 60898/C MCB. The sub-main wiring consists of 10.00 mm 6491x cables encased in 50 mm x 50.00 mm trunking inside the workshop, joining to a 10.00 mm 2-core SWA cable buried underground.

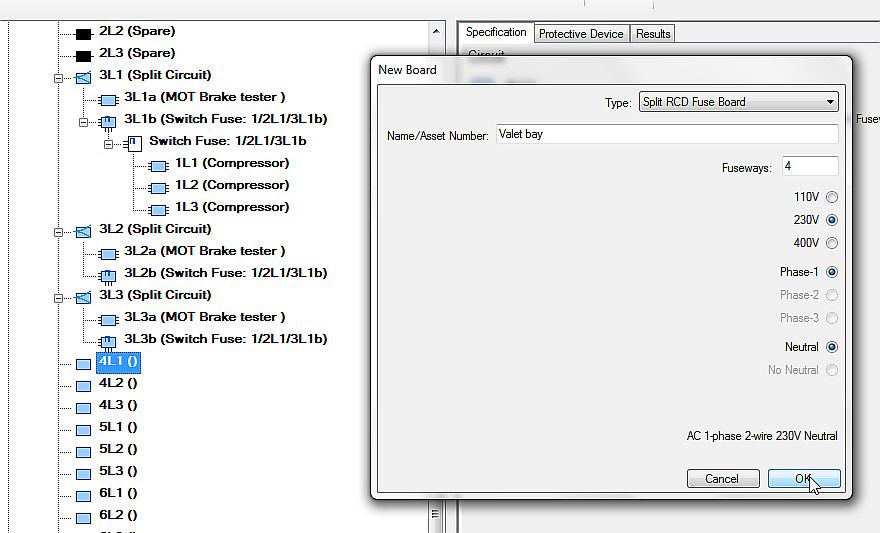

Create a new board and in the New Board dialog under “Type” select “Split RCD Board”.

-> Creating a Board

Select the circuit that feeds the board and add sub-main cables.

As you can see, the SWA cable has a carrying capacity of 57 amps, which, subject to the load downstream, may not be an over load risk. Although there are 2 differing types of cables in series feeding this fuse board, the sub-main circuit shows both types. On the downstream fuse board it only shows the actual cable connected to it. To enable the correct cable to be shown physically connected to the downstream fuse board, you must as per the “Note: If more than….” under “Circuit Cable in Series”, work from the load end back to the supply.

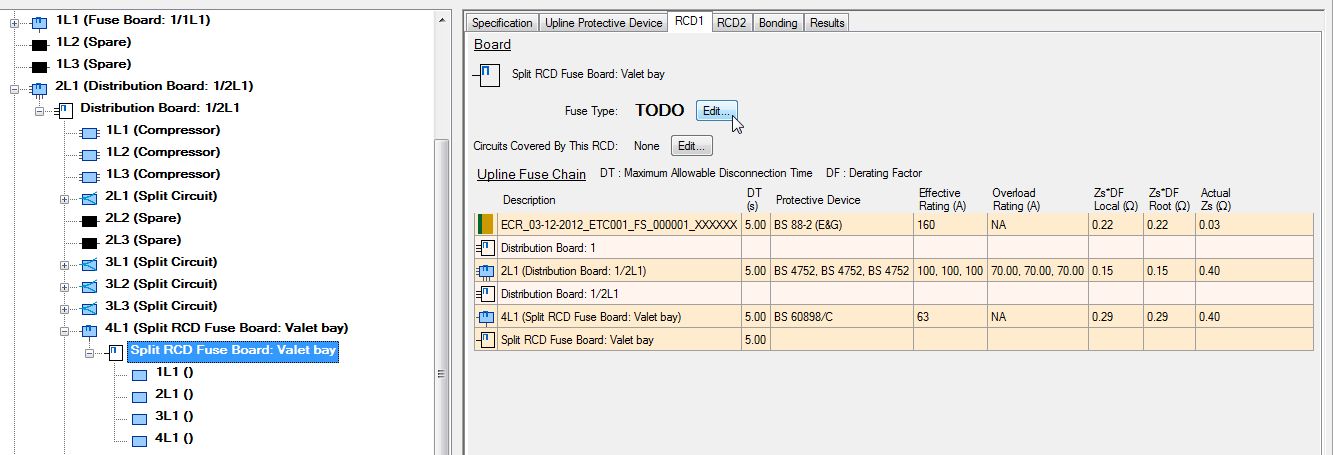

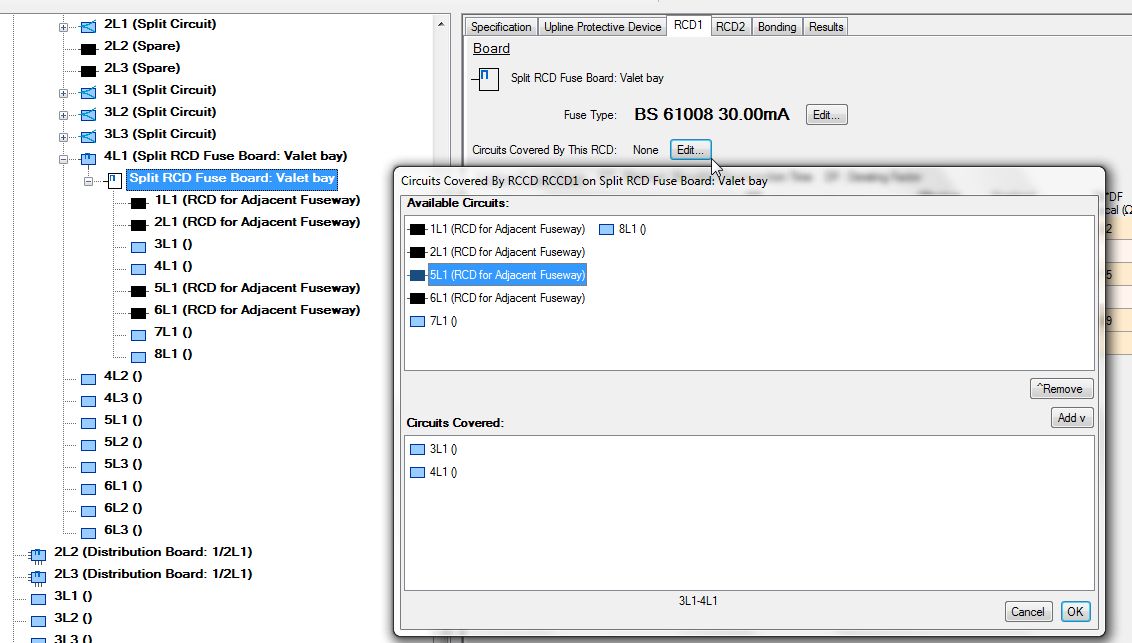

We now need to enter the RCD details and allocate the fuseways protected by RCD 1.

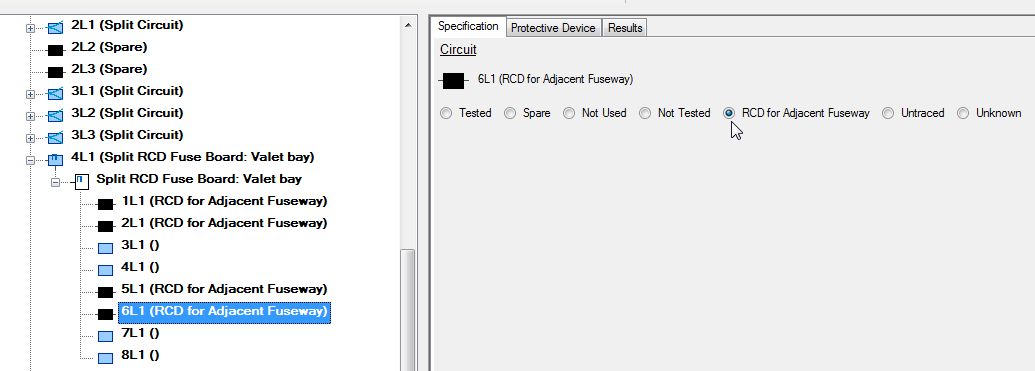

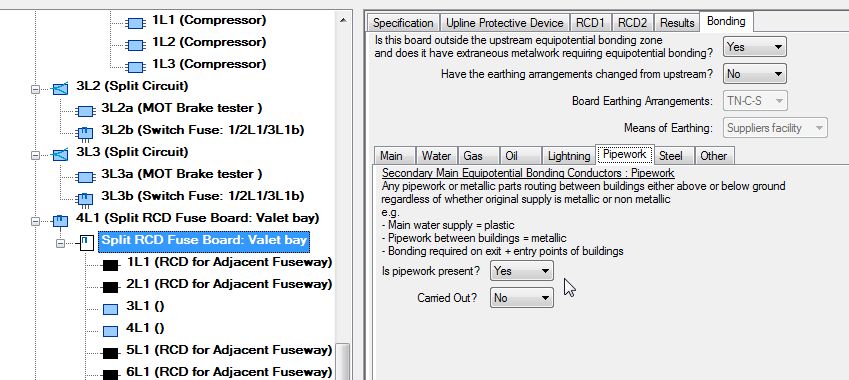

To make it “visually” correct you are able to enter “RCD for Adjacent Fuseway” if required.

- In the left tree, select the board, select the “RCD1” tab, then enter the RCD details.

- Now allocate the fuseways protected by RCD1 by highlighting the relevant circuits and “Add” them into the bottom pane. If you make a mistake, again highlight the circuits and use the “Remove” button.

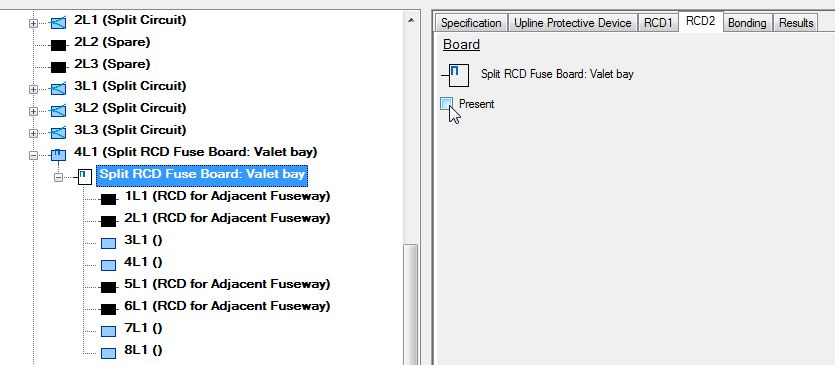

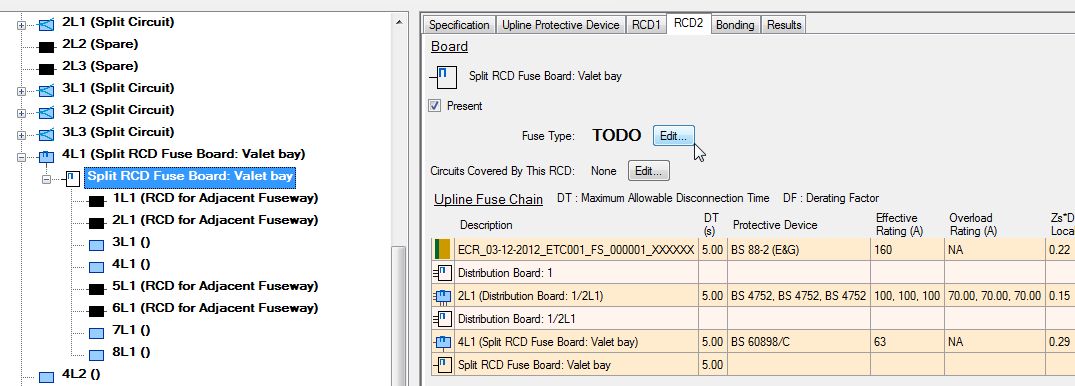

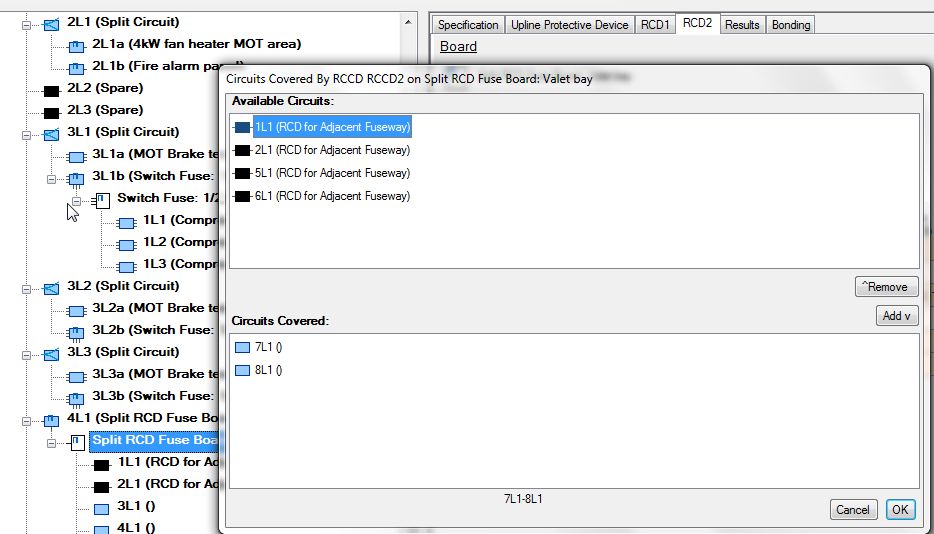

- If there was not a second RCD then the “RCD2” tab is ignored. If, as in this example, there is a second RCD, open the RCD2 tab and tick the “Present” box.

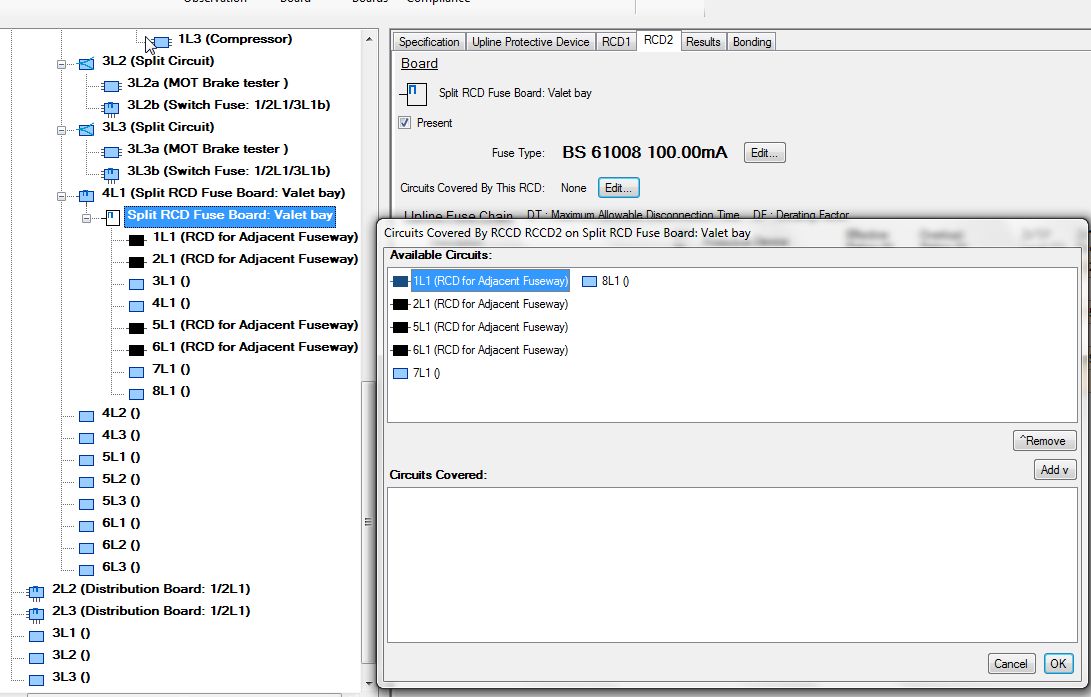

- Carry on and enter the details of the second RCD. Do not forget to allocate the “Circuits covered by….”!

- Enter the RCD 2 details. On opening “Circuits Covered By This RCD”, you can see that only the circuits (in blue) that have not been covered by another RCD are available to save possible errors.

- Choose the appropriate circuits covered by RCD 2.

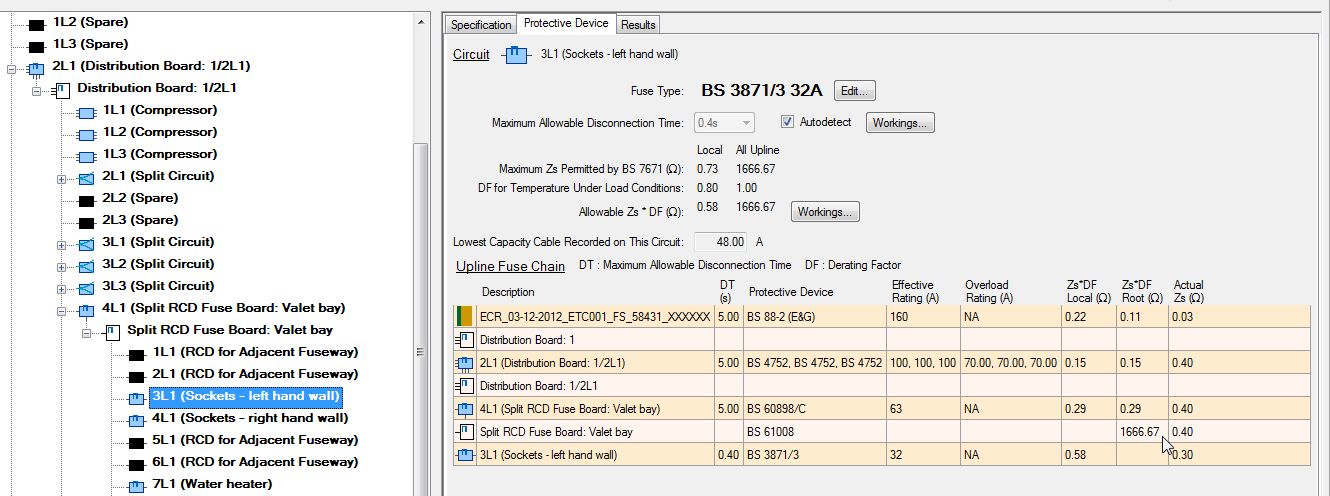

- Go to the “Protective Device” tab to confirm that you have allocated the required circuits to each RCD.

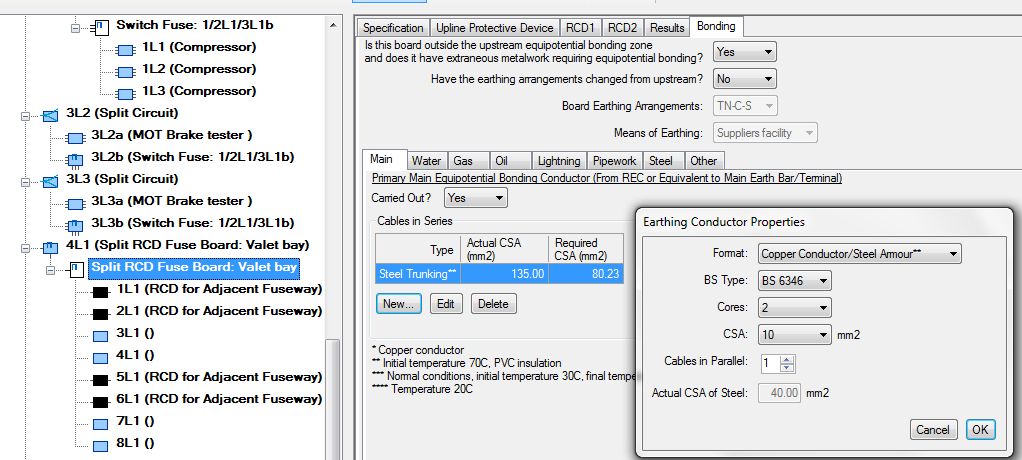

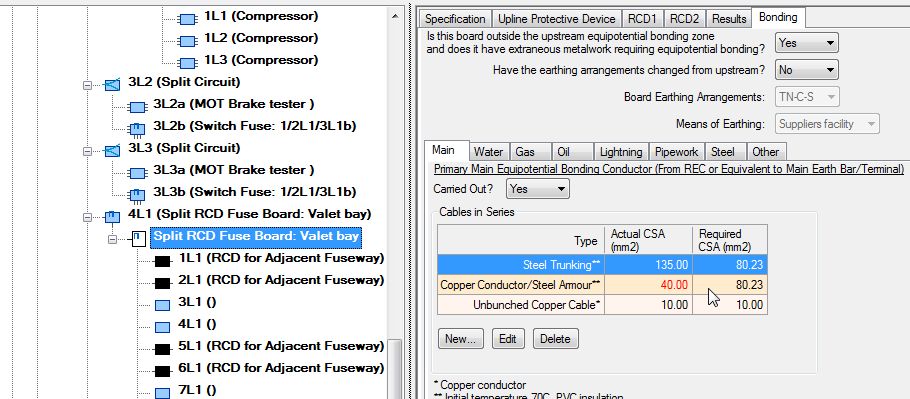

We now need to record the bonding system for the Valet Bay. The Valet Bay is situated in a steel structure having a copper water supply and a steel air-line fed overhead from the main building. The TNCS earthing system has been exported to this building - therefore, verification of the bonding cables are required in relation to the supply neutral supplying the main building. The supply to this building is wired using 10.00 mm 6491x single insulated cables utilising the 50 mm x 50 mm trunking and a buried 2-core 10.00 mm swa cable. Therefore, the CPC and main bonding conductor are made up by both the trunking and armouring. We first need to record the steel trunking, which as shown, has been recorded; we will now record the armouring of the SWA.

Let us assume that there is a MET (main earthing terminal) in the Valet Bay which is being used rather than the earth terminal bar inside the fuse board. Therefore, we also need to record the main bonding conductor from the fuse board earth bar to the MET (10.00 mm earth cable). We have now entered the “Main” earth bonding for the Valet Bay showing the steel trunking, the armouring of the SWA cable connected to the fuse board and from the fuse board, the 10.00 mm earth cable connected to the MET. You can see the required CSA (mm) in the right hand column with the actual sizes recorded. Where there is an undersized bonding cable, this will be highlighted in red as in the case of the steel armour. This will automatically offer an automatic observation when you click the |check compliance icon| button later.

- Enter the bonding for the copper water supply, the steel structure and the steel air-line which is fed overhead from the main building and as it is isolated from the structural steel work, requires a separate equipotential bonding conductor. This bonding has not been carried out and as a result, the software will offer an automatic observation when you click the |check compliance icon| button later.

- Note:

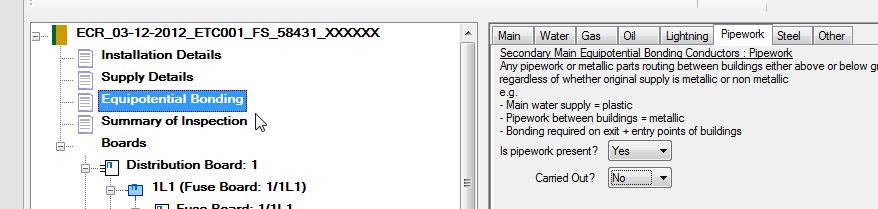

- If not already done, remember to record the “Pipe-work between buildings” on the Site “Equipotential Bonding” “Pipework” tab with regard to the air-line.

➲ Next: Record an R1 + R2 and R2 Test.